Advanced Metal Coatings is a one-stop shop. This means more accountability. If a coating doesn’t meet standards, you don’t want a situation where the company that did the powder coating blames it on the company that did the passivation and vice-versa.

Since we take your projects all the way from prep to shipping, we make sure that all the steps are completed to the highest level specifications.

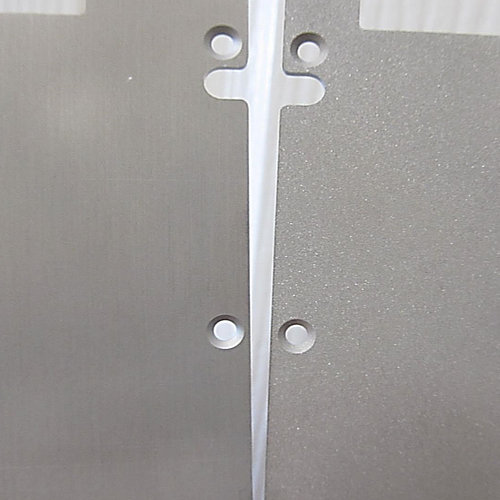

Passivation removes surface impurities that cause corrosion and promote friction-related damage in stainless steel. The result is a protective film that won’t create a variation in component tolerances.

Passivation removes the surface contamination created when stainless steel is machined and fabricated. These contaminants can result in premature corrosion that could ultimately damage the component. In addition to surface cleaning, passivation forms a thin, transparent oxide coating that fights selective oxidation.

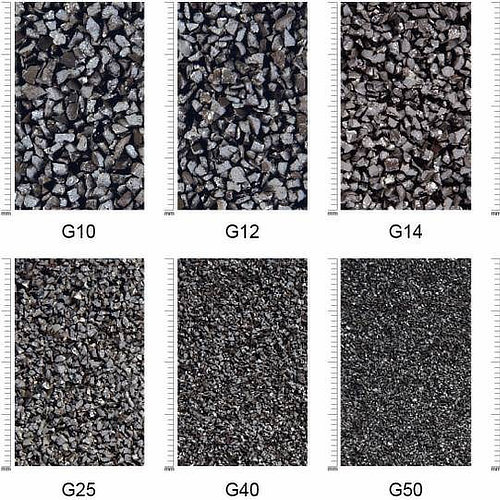

Abrasive blasting is generally used to replace sanding, wire brushing and pickling. Ordinarily, no other cleaning is necessary because the blasted surface is mechanically cleaned.

Abrasive blasting can save from 25% to 75% of the time normally required by hand cleaning, while producing a superior cleaned surface ready for coating. This saves the customer money spent on labor, and ensures a quicker turnaround time.

Abrasive blasting can make a good finish better and cleaner. It also produces a better tooth for bonding. It is estimated that the surface area of metal increases as much as ten times as a result of the abrasive impact action. This increases the surface to which paint, coating or plating can adhere.

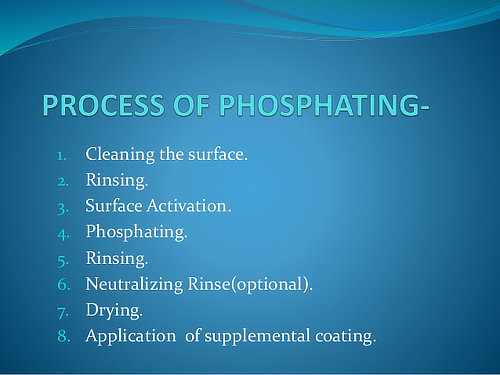

Phosphating, or conversion coating, is the application of an iron or zinc phosphate coating to the substrate. Conversion coating can be a very critical part of the pretreatment process, adding significantly to the performance of the finished coating.

A phosphate coating converts the metal substrate to a uniform, inert surface, which improves bonding, minimizes the spread of oxidation if the coating is scratchedand improves the overall corrosion resistance of the final part.

A conversion coating can be iron, zinc, polycrystalline, chromate, or manganese phosphate film. They are developed on both ferrous (iron based) and non-ferrous surfaces (zinc, aluminum, terne and manganese).

Parts are subjected to an acidic bath and a chemical conversion forms a complete film on the part surface, changing the chemical and physical nature of the metal surface.

Chemical film coating is also referred to as Chem Film or Chromate Conversion. These terms all refer to essentially the same process, the electrochemical application of a chromate conversion coating on aluminum. Chem film coating produces a finish which protects from corrosion, assures good paint adhesion and conducts electricity.

Cast parts often have air trapped in the metal. If the air expands while powder coat is heated, it can leave pinprick holes in the surface.

We preheat all cast parts to remove gas contaminants.

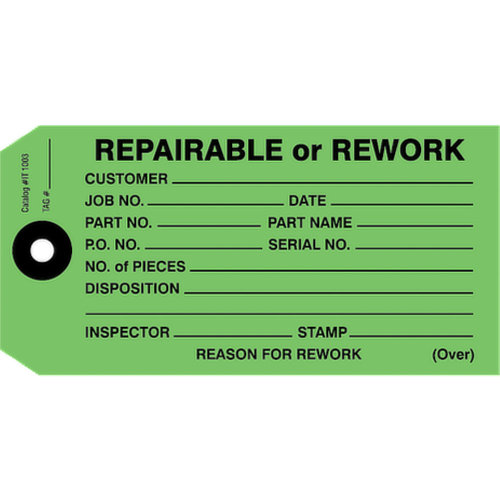

A good part of our business involves fixing other people’s mistakes. We can strip and repaint or recoat parts with paint or powdercoat that is patchy, powdery or peeling.

Call us to get the job done right!.

You are also welcome to give us a call at 727-744-9508